precise craftsmanship

No matter the size of the product, every piece comes from ingenuity, precise craftsmanship, careful attitude, excellent technology, advanced equipment, to achieve every piece of high-quality goods.

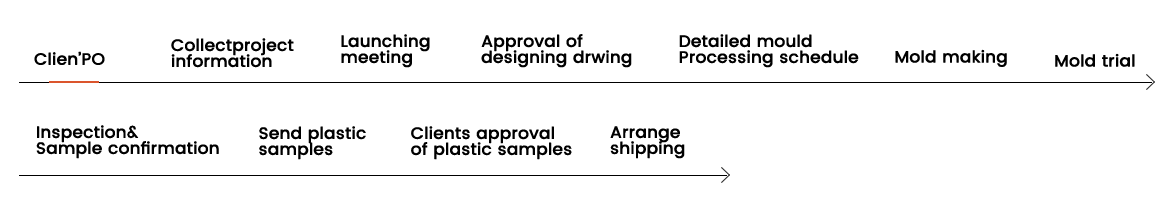

Efficient Service/Achievement Value

Focus on products, actively participate in customer design, provide customers with feasible solutions. Strict quality control, for customer achievement value, but also for enterprise achievement value.